What is STICK Welding? (SMAW)

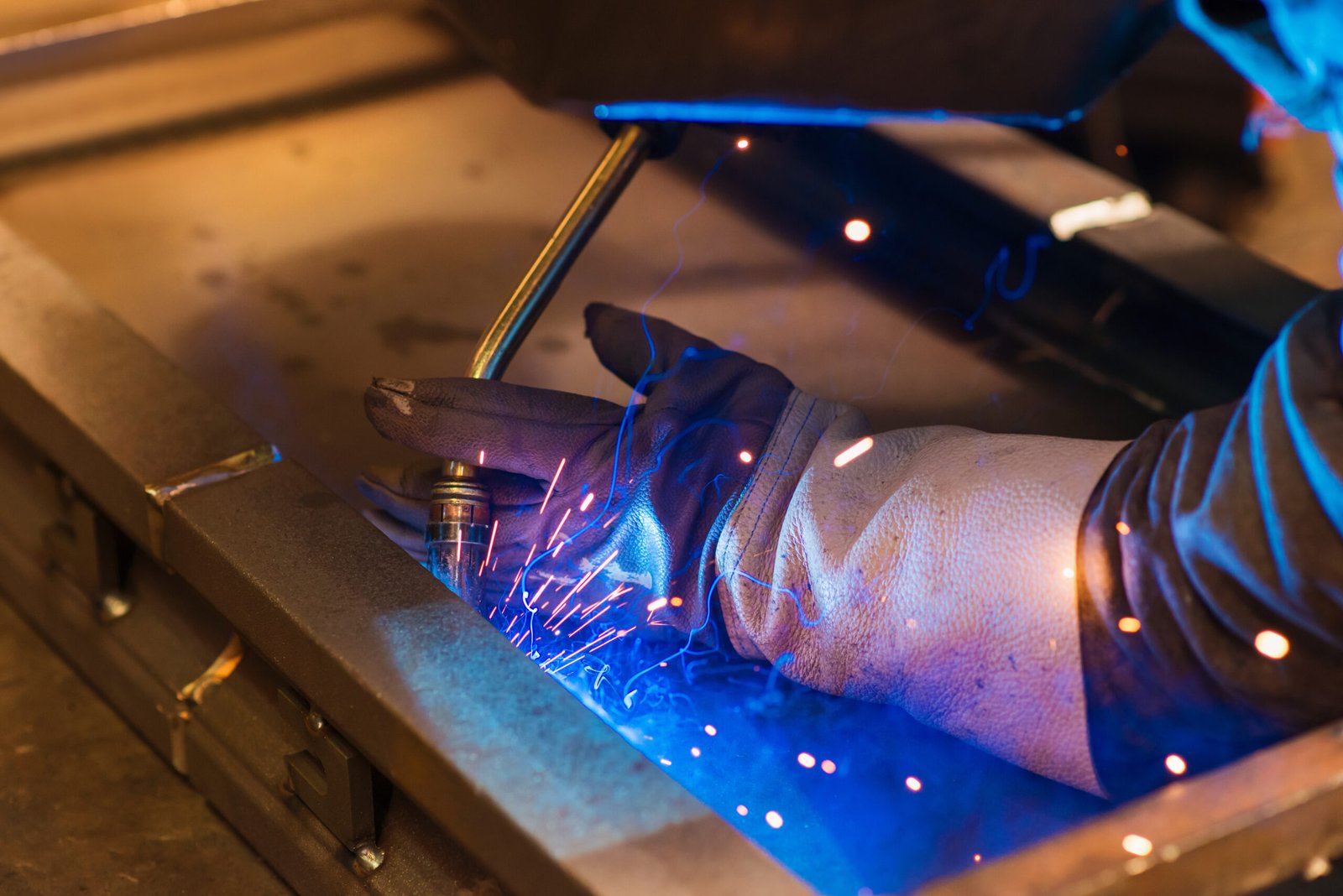

STICK welding is a welding technique that is often used to weld thin metal sheets. This welding technique is often done with an electrode-covered welding rod that produces a filler metal (arc).

The welding rod (or welding wire) is fed by hand at the end of the welding arc. The arc heats the welding rod until it melts and solidifies, producing enough heat to melt nearby metal molecules together. This welding technique can produce high-quality welds on materials like sheet steel.

STICK welding is also called shielded metal arc welding (SMAW) and manual metal arc welding (MMAW).

What features does a welding helmet have?

A welding helmet protects the welder from ultraviolet rays, sparks, spatter, heat and most importantly from harmful radiation. Welding helmets also provide limited vision protection from flying objects. A welding helmet has several components which vary by application:

– a wire/window to protect the lens

– a filter lens for different welding tasks

– a shade level with a number rating corresponding to how much light is transmitted through the lens

– screen/handle assembly for easy placement over head. There are 2 styles of screens – one being the welding screen where the welding cable attaches, and the welding cap with no cable.

How to use a welding helmet? (How do you wear it)

– Welding helmets are designed to protect your eyes during welding operations. They feature one or more lenses that can be raised on either side of the head by means of an operating lever on the left side for the right eye and on the right side for the left eye.

– The shade of lens should be selected according to the type of welding operation being done and light conditions present in your work area at any given time during your welding job. The shade number is indicated by the color under each lens of your welding helmet.

– The welding screen is meant to protect the welding lenses against welding spatter and sparks. It can be lifted up so that it does not obstruct your vision of the welding job, but will prevent welding spatter from hitting the welding lenses of your welding helmet. Make sure you do not exceed the heat resistance limit of your welding screen by using it as a handle or an extension of your arm near the welding arc.

– While some helmets are equipped with sight windows above both lenses, others glasses which cannot be raised up like conventional safety glass due to the fixed position of its frame across both sides on the top portion of them; instead they are permanently fixed in one position providing excellent protection during welding jobs done through shielded metal-arc welding (SMAW) processes.

– To protect welding screens against welding spatter, you should avoid touching them with your hands. If welding screens are covered in welding spatter or do not completely cover the welding lenses, you can clean them by wiping the welding spatter off the welding screen with a damp cloth or scraping it away with your fingers if it is in small particles.

– Should your welding helmet have an adjustable headband for mounting, adjust so that when in use the helmet fits snugly over the top of your eyes and temples to help prevent possible injury from flying objects hitting you in this area during hot starts or other situations where sparking occurs. This would normally be adjusted just after putting on the helmet by pulling back slightly on both sides of the welding helmet assembly.

– The welding cap or welding bonnet is designed to protect welding lenses from welding spatter and sparks, but not from the heat. It also provides a means for applying welding smoke with a spray gun without removing your welding helmet. In most cases, this is done using a welding screen around the perimeter of the welding cap to prevent metal spatter from getting inside it. This is important as any metal deposited inside can cause shorts within electrical components in contact with the coating on these screens after removing your welding helmet.

For best welding service near me call now.

Related Article: https://en.wikipedia.org/wiki/Welding